Hydrotreated Vegetable Oil (HVO), also known as ‘renewable diesel,’ is produced through catalytic hydroprocessing of oils and fats. Compatible with petroleum diesel, HVO can be upgraded to ‘Sustainable Aviation Fuel’ (SAF). Our pre-treatment processes clean the raw materials to protect the catalyst used in HVO/SAF plants by efficiently removing the contaminants (phosphorus, metals, etc.) from the feedstock blends.

How does it work?

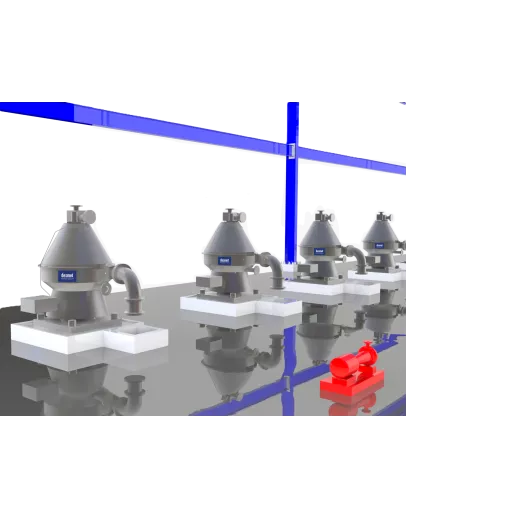

Desmet, active in HVO pre-treatment since 2007, offers a proven process based on over 75 years of experience in vegetable oils and fats processing for almost any feedstock, ensuring high reliability and efficiency. Today, we have multiple plants in full operation with a daily capacity of >20.000 tpd (>140.000 bpd).

In our processes HVO can be produced from a wide variety of raw materials containing triglycerides and fatty acids: vegetable oils, animal fats and a wide range of waste and by-products from oils and fats processing, like used cooking oils (UCO), fatty acid distillates, acid oils, etc.

Full process

We supply a proven, highly reliable and efficient process that can accept almost any feedstock blend and will provide you an in-spec product suitable for HVO processing. From oils and fats to pretreated HVO and SAF feedstock - Desmet delivers.

Key advantages

Desmet’s HVO pre-treatment process offers several key advantages.

Efficiency

Our process design ensures low utilities and chemical consumption, reduced effluents by recycling process water, and compact equipment for quick startup and shutdown.

Flexibility

Maximum feedstock flexibility to accommodate various raw materials and blends.

Reliability

High reliability, operating up to 8500 hours per year with simple, proven mechanical designs that require low maintenance.

Safety

Safety issues are meticulously studied (HAZOP) and implemented to ensure secure operations.

Automation

Desmet’s in-house automation team ensures consistently clean feedstock to avoid downtime, protect HVO catalysts, and optimize the process.

Performance

Our plants, designed with high capacity ranges (up to 5000 tpd and more) and high availability (>95%), meet market expectations and deliver exceptional performance.

Raw materials

Biofuels can be produced from various fatty acids containing feedstocks like animal fats, vegetable oils and used cooking oil, depending on the region. Our plants can be customized based on local availability of feedstocks, with additional sections for enhanced cleaning and optimized performance.

Key proprietary equipment

Desmet provides advanced degumming and bleaching processes for HVO pre-treatment. Degumming removes the bulk of impurities such as phosphorus and metals. The dry pre-treatment process followed by bleaching, effectively eliminates residual contaminants, achieving the low phosphorus (<3 ppm) and total metals (<10 ppm) levels required by the HVO licensors. The pre-treatment plants are fully and carefully designed by the Desmet engineering teams, to meet the high quality and performance expectations of this new industry.

Our services

With a focus on cutting-edge technology, high-quality components, and comprehensive on-site support, our service teams ensure optimized plant performance and minimized operational disruptions.