Full pressing

With 250 years of experience, RoseDowns delivers comprehensive pressing solutions designed to maximise oil extraction from oilseeds & nuts, while preserving protein quality. At the heart of the process is the renowned Sterling Series screw press. Desmet, with over 80 years of experience, offers comprehensive extraction solutions and fully integrated technology packages tailored to meet industry-specific needs. Whether for cold or hot pressing, Desmet provides options for cookers, extruders, and single or double-stage setups. Together, RoseDowns and Desmet combine their extensive expertise to deliver superior pressing solutions that meet the highest industry standards.

How does it work?

The key to an effective separation process in oils is proper mechanical, and sometimes thermal, preparation before screw-pressing. After separation, oils and the solid protein-containing cake must be processed carefully to preserve their nutritional or technical value. Desmet masters all aspects of preparation, screw-pressing, and further processing, offering customised solutions for each full press application.

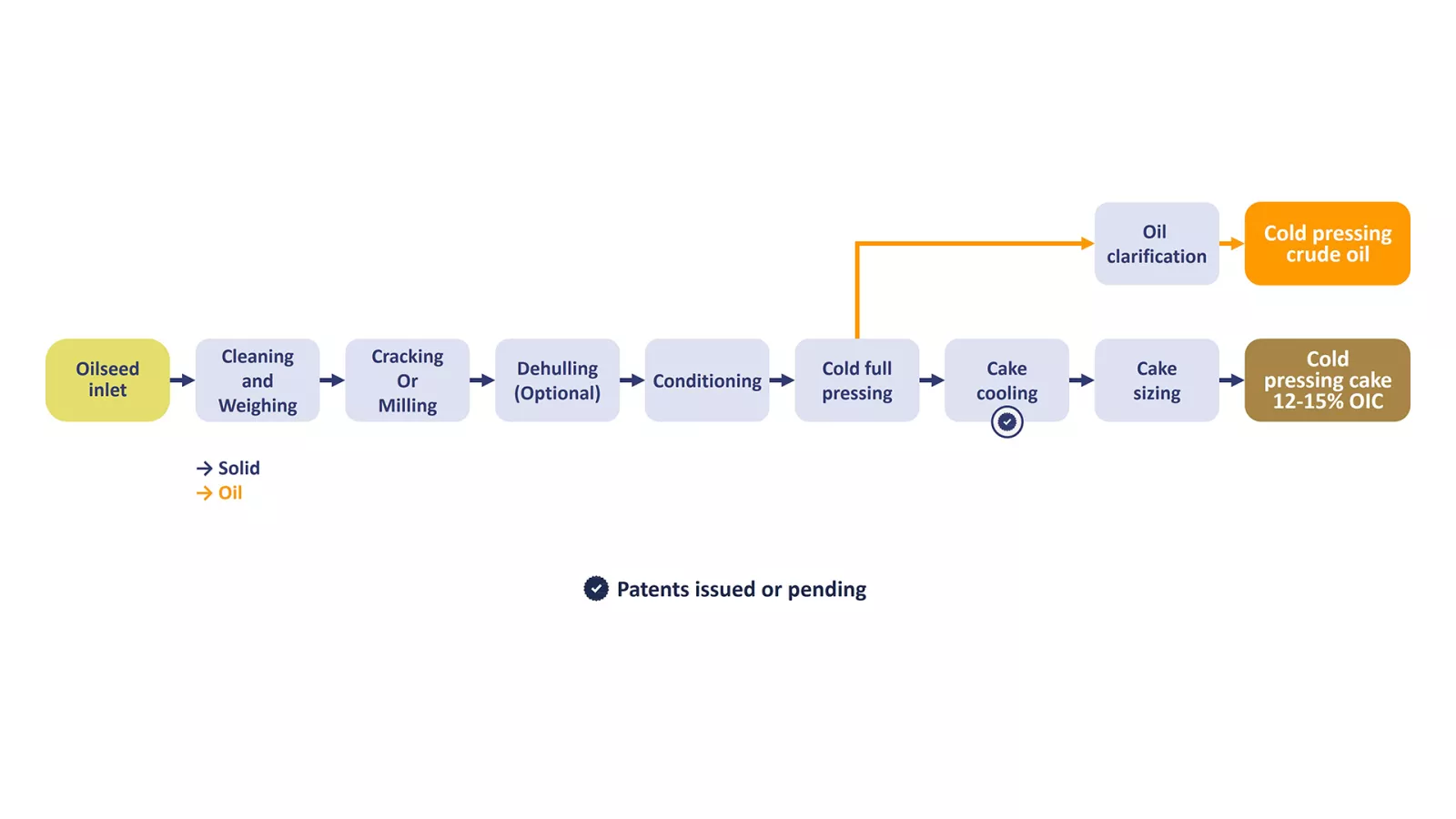

The oilseed full pressing process may include the following steps:

- Seed conditioning: adjusting moisture and temperature for optimal processing

- Cracking: reducing seed particle size

- Seed dehulling: removing shell to increase protein content in the de-oiled cake

- Flaking: rupturing the cell structure of broken seeds

- Cooking: reducing oil viscosity and adjusting moisture for improved press performance

- Dry extrusion: an alternative to cooking and flaking

- Pre-pressing: recovering easily extractable oil in multi-stage pressing

- Full pressing: recovering maximum oil

- Oil clarification: removing suspended solids from crude oil

- Cake cooling: reducing cake temperature before storage

Full pressing can be done with either ambient or heated feed materials, leading to two process variants: cold pressing and hot pressing.

Cold pressing

Cold pressing is recommended for the highest quality oils whilst preserving the cake's protein quality. The feed material should enter the press at ambient temperature, though pre-conditioning may be required in colder climates to adjust temperature and moisture levels.

To maintain temperatures between 60°C and 70°C in the press cage, and maximize oil recovery while preserving protein, the screw shaft operates at a lower speed. Crude oil and suspended solids (foots) are separated during oil clarification, and the de-oiled cake is cooled before storage.

Due to the relatively low process temperature, the moisture in cold-pressed oil may be too high for storage and may require drying before clarification. Cold-pressed oil generally has fewer gums, and a lighter color compared to hot-pressed oil, making it suitable for physical refining or direct bottling in some cases. The cold-pressed cake retains high protein quality, making it ideal for specific food applications like protein isolates.

Advantages of cold pressing

Protein quality

The limited temperature rise in the press cage ensures that the cake's protein remains unaffected by the process.

Oil quality

Cold-pressed oil can command a premium value in the market.

Hot pressing

Hot pressing is recommended when the focus is on maximizing oil yield and increasing cake protein concentration. The feed material typically enters the press at 105 – 120°C with 2-4% moisture. To achieve these conditions properly prepared oilseeds are heated in a cooker by indirect steam contact and dried using counter-current airflow.

Friction on the cooked seeds inside the press cage allows for a high oil extraction rate, leaving the cake with 7 to 10% residual oil at the outlet.

Due to the high process temperature, moisture in the oil evaporates. After decanting, where most suspended solids are removed, the oil is filtered and cooled before storage. The hot press cake, discharged at around 120°C, is cooled using counter-current airflow before storage.

Advantages of hot pressing

Oil yield

Hot pressing achieves a higher oil extraction rate, making it ideal when oil is the main product.

CAPEX

Mechanical extraction is simpler than solvent extraction, making full pressing suitable for projects with lower CAPEX and shorter lead times.

Flexibility

Hot full pressing is easily customizable for multi-seed processing projects.

Extrusion-Pressing

When it comes to pressing, there is an alternative method that is particularly effective under specific conditions. Extrusion-pressing is highly recommended when the primary goals are maximizing oil yield and enhancing the concentration and quality of cake protein. This method is also ideal for production sites where steam is not available.

Learn more about how extrusion-pressing can meet your unique requirements and optimize your production process.

Raw materials

Desmet's full pressing solutions are designed to handle a wide range of raw materials, including rapeseed, sunflower, soybeans, linseed, mustard seed, ground nuts, shea nuts, and cocoa beans for efficient oil extraction.

Key proprietary equipment

The full pressing process relies on advanced equipment, including conditioners, presses, and vertical cookers, specially designed to optimize seed preparation, enhance oil extraction, and ensure maximum efficiency in feed production.

Our services

With a focus on cutting-edge technology, high-quality components, and comprehensive on-site support, our service teams ensure optimized plant performance and minimized operational disruptions.