Rendering

RoseDowns advanced design and manufacturing expertise play a crucial role in the efficient processing of animal by-products and other food waste. With the increasing global demand for oils and fats, RoseDowns has developed a new generation of rendering presses. These presses are engineered to deliver the highest level of reliability and performance, meeting the rigorous standards of modern rendering plants.

How does it work?

At RoseDowns, we design and manufacture screw presses specifically for processing animal by-products. Our primary goal is to efficiently separate the solid and lipid phases. While small amounts of fat and water may remain in the solids, our pressing solutions are engineered to ensure optimal separation and product stability.

The key outputs of the rendering process are animal proteins and oil/fats, both carefully refined to achieve maximum stability with minimal water and solid content.

Key advantages

RoseDowns rendering presses offer numerous benefits for modern plants.

Yield

Achieve maximum output with minimal waste.

Maintenance

Enjoy longer parts life with all-inclusive maintenance.

Support

Benefit from flat-rate monthly maintenance, including spares.

Safety

Guaranteed safety controls for worry-free operations.

Efficiency

Improved fat extraction and extended spares wear life.

Profit

Better defatting leads to increased profitability.

Raw materials

Our screw presses are engineered to efficiently process a variety of animal by-products and larvae. This capability ensures optimal separation of the solid and lipid phases, maximizing yield and profitability while maintaining high standards of reliability and performance.

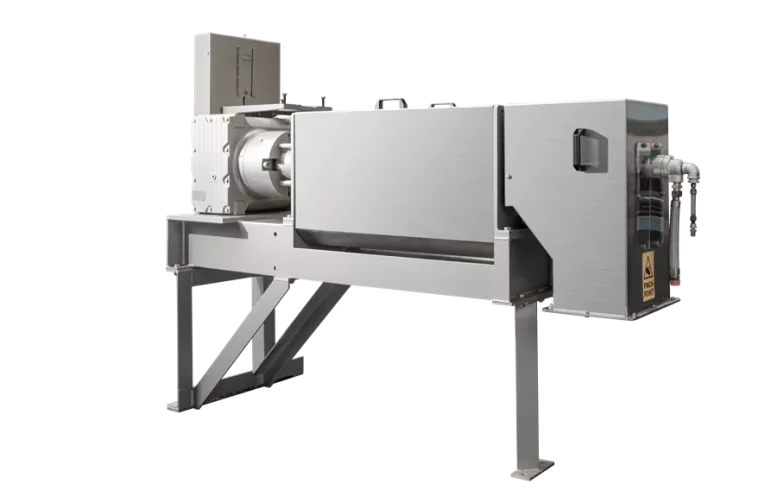

Key proprietary equipment

RoseDowns engineers have developed cutting-edge rendering presses, designed to deliver superior efficiency and durability. These presses are specifically engineered to process raw materials into valuable oils and fats, ensuring optimal output while minimizing operational costs. Their advanced design helps rendering plants meet the rigorous demands of modern industry, increasing efficiency, minimising downtime and improving health and safety.

Our services

With a focus on cutting-edge technology, high-quality components, and comprehensive on-site support, our service teams ensure optimized plant performance and minimized operational disruptions.