Oils & Fats refining

Crude vegetable and animal oils and fats, produced by rendering, pressing and/or solvent extraction can contain various minor components like free fatty acids (ffa), partial glycerides, phosphatides, oxidation products, sterols, tocopherols, pigments, protein fragments, and traces of contaminants, pesticides and heavy metals.

The refining processes allow to eliminate unwanted components in a controlled way to produce edible vegetable and animal oils and fats, ensuring they meet the stringent food safety and quality standards required by the industry and end-consumers.

How does it work?

The refining process involves several unit operations that can be combined and optimized to achieve the highest edible oil quality. Unwanted components are gradually removed during refining, ensuring minimal loss of desirable elements. The industry generally uses two refining routes:

- Chemical refining is a robust and forgiving process primarily used for sometimes difficult vegetable oils like soybean and rapeseed oils. The process includes a (combined) degumming and neutralization, bleaching, and deodorizing. For some wax containing oils, such as sunflower and corn, an additional winterizing step can be added. A key feature is the removal of FFA during neutralization as soaps using caustic soda. The heavy phase, so called soapstock, is separated by centrifugation.

- Physical refining is primarily used for high-FFA oils like palm, palm kernel, and coconut oil, but also for some soft oils like sunflower and corn oil. In this process, free fatty acids are removed during the deodorization step by steam stripping as a distillate. The process steps include acid, (optional) enzymatic deep degumming, bleaching, stripping-deodorizing, and optional winterizing. Physical refining generally results in lower product losses, particularly for high-FFA oils.

Full process

To illustrate the two oil refining routes mentioned above, we provide a detailed flowchart below. The diagram outlines each process step, from crude vegetable and animal oils and fats to the final refined oils and fats to be used in edible products.

Key advantages

The Desmet refining technology for oils and fats delivers the highest standards in terms of oil quality, plant reliability and safety.

Quality

Organoleptic as well as visual appearance, shelf life, nutritional and food safety requirements of our customers.

Safety

Plant design including HAZOP and automation assures the highest levels of safety.

Reliability

Equipment standardization, design, and quality control ensure robust and reliable plants for our customers.

Customization

Flexible, efficient and highly automated plants tailored to specific customers' needs.

Raw materials

Desmet is specialized in refining common raw materials such as palm oil, soybean oil, rapeseed oil, and sunflower oil into high-quality refined oils. We also have extensive experience with refining less common raw materials like fish oils, rice bran oil, cocoa butter, shea butter, coconut oil, and more. All these oils are processed to meet the highest standards of purity, nutritional value, and quality required by the food industry.

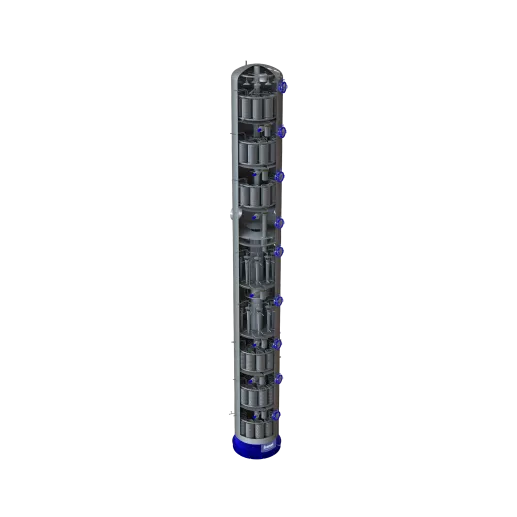

Key proprietary equipment

Our oil refining processes use advanced proprietary equipment designed to the highest industry standards, ensuring the best quality end-products. Key proprietary equipment includes bleachers, deodorizers and vacuum systems. This equipment is integrated into complete oil refineries, which are fully and carefully designed by the Desmet engineering teams.

Our services

With a focus on cutting-edge technology, high-quality components, and comprehensive on-site support, our service teams ensure optimized plant performance and minimized operational disruptions.